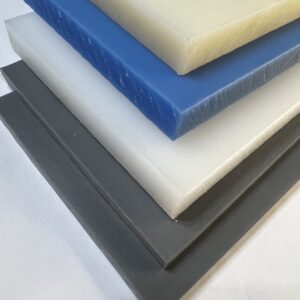

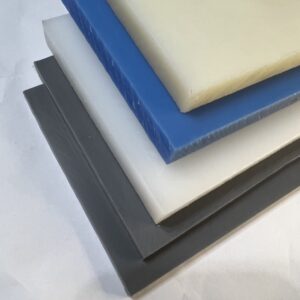

Nylon (Super Nylon) - PA6 (Polyamide 6)

Super Nylon, also known as Nylon 6 or PA6 (Polyamide 6), is an engineering plastic categorized as a thermoplastic polyamide derived from the polymerization process of amide and organic acid. The addition of additives such as graphite and molybdenum disulfide helps enhance its properties.

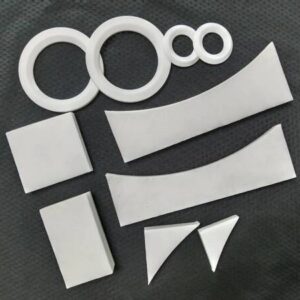

Applications: Super Nylon has a wide range of applications, particularly in industries. It can be used in turning-milling operations to manufacture various machine parts and components such as bushings, pulleys, gears, valves, bumpers, and worktables.

Properties of Super Nylon PA6 Sheets and Bars

- Resistant to abrasion and color fading, maintains shape integrity.

- Suitable for applications requiring high strength.

- Hardness: 70-82 Shore D.

- Suitable for use in temperatures ranging from -40 to 85 °C.

- Begins to deform at 75 °C under pressure.

- Maximum Operating Temperature: Up to 120 °C (melting point 180-200 °C).

- Has no taste or odor, non-hazardous.

- Can be heat sealed at high temperatures.

- High expandability and excellent flexibility, resistant to tensile and tear forces.

- Resistant to chemicals and scratching.

- Highly absorbent to water.

- Effective barrier against fat, oxygen, and various odors.

- Retains strength and resists gas permeation with increased humidity.

Super Nylon PA6 is therefore a suitable material for industries requiring high durability and flexibility.