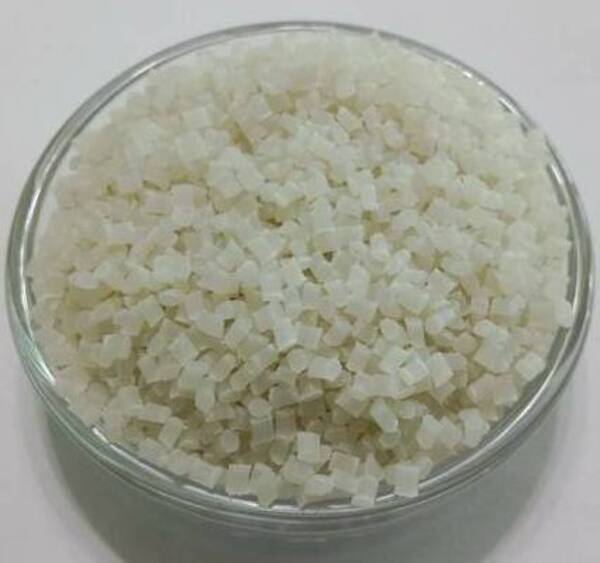

Nylon 6 + Fiber Glass

Nylon 6 blended with fiber glass is a composite material combining Nylon 6 and fiber glass to enhance strength and mechanical properties. This material is commonly used in applications requiring high strength and durability against impact.

Applications:

- Automotive Industry: Used to manufacture various parts such as car body shells, engine covers, air vent systems, and interior components.

- Mechanical engineering: Used for pulleys, bearings, wheels, rollers, and machine components requiring high strength.

- Electrical and electronics industry: Used for electrical insulation, cable supports, and connectors.

- Construction Industry: Used in construction applications requiring materials with high strength and weather resistance.

- Electronics Industry: Used to produce components requiring high strength and heavy-duty performance.

- Packaging Industry: Used to manufacture packaging requiring high strength and durability.

Features

- High Strength: Reinforced with fiber glass, Nylon 6 + Fiber Glass has higher mechanical strength compared to regular Nylon 6.

- Impact and Abrasion Resistance: Highly resistant to impact and abrasion, suitable for heavy-duty applications.

- Chemical Resistance: Resistant to various chemicals, including acids and bases.

- High-Temperature Resistance: Can withstand high temperatures effectively.

- Dimensional Stability: High dimensional stability, maintains shape and size integrity even with temperature and humidity changes.

- Low coefficient of friction: Smooth and lubricated movement, suitable for parts requiring smooth motion.

- Lightweight: Despite the fiber glass reinforcement, Nylon 6 remains lightweight, facilitating ease of use and mobility.

- High Impact Strength: Nylon 6 + Fiber Glass exhibits high impact resistance, suitable for applications requiring durability against impacts.

- Environmental Resistance: Resistant to various environmental conditions such as moisture and UV light.